|

|

SUWADA Nail NipperSUWADA Blacksmith Works is located in the city of Sanjo, Niigata Prefecture, Japan, a place long known as one of the world’s leading production centres for high-end cutlery. In 1926, the founder, Shukusaburo Kobayashi, began manufacturing kuikiri (end-cut pliers), for carpenters in response to surging demand for new housing in the wake of the Great Kanto Earthquake of 1923. |

|

|

FEATURES

|

|

|

|

|

|

|

SUWADA's nail nippers are made of round rods of high-carbon stainless steel. They are carefully selected materials, and all smelted in Japan

|

|

|

|

|

A round rod heated to high temperature over 1000 degrees is forged with 400 tons of pressure. The material is trained heavily. The craftsmen breathe new life into the steel.

|

|

|

|

|

The forged rod is cut out according to the mold. Only the central part, approximately 30% of the rod, can become nail nippers.

|

|

|

|

|

All processes are done by hands of skilled craftsmen. Their small, delicate and proper works pile up and make the basis of function and beautry.

|

|

|

|

|

The left and right parts cut out are riveted. Eventually they become the original "shape" of nail nippers.

|

|

|

|

|

Craftsmen polish the nippers using sandpapers of many different specifications from coarse ones to finer ones. They bring these pieces to their ultimate beauty in form.

|

|

|

|

|

Craftsmen adjusts the blades in increments of 1/1,000 millimeter for the perfect finish with no gap. Through these processes with the final inspection, our products become the best ones.

|

|

|

|

|

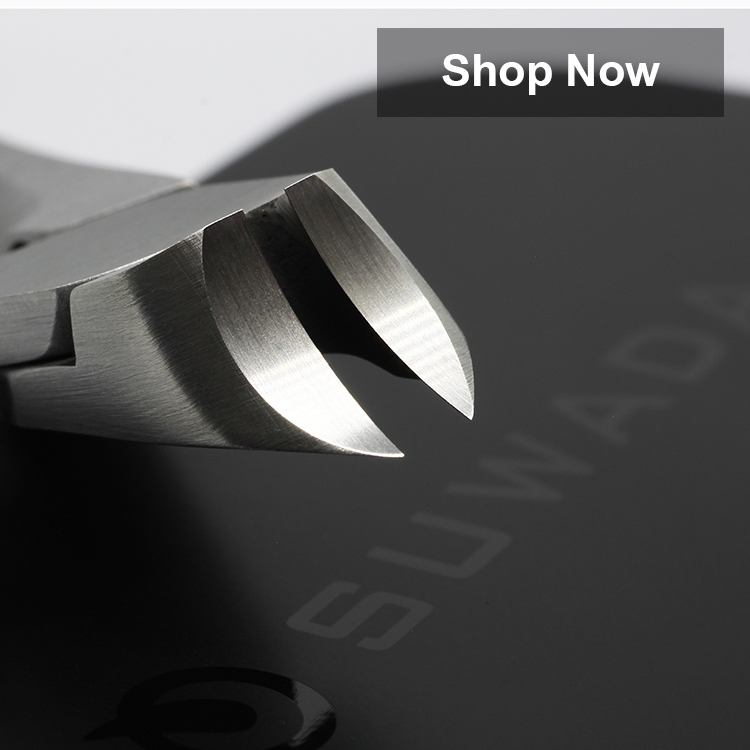

Extremely thin blades are formed with gentle curve which fits the line of nails. The sharpness of edge is trusted by professionals and discerning consumers.

|

|